Machining

Laser machining is especially adequate for rapid prototyping of complex structures. For example, the implementation of direct laser writing utilizing digital layouts is a straightforward method to support and test new product developments. But also in batch production the laser machining offers new possibilities to slim fabrication chains and reduce production cost.

A well configurated laser working station characterizes a highly flexible tool which can complete several machining tasks, e.g. drilling, cutting, selective layer removal and marking of circuit boards. In the frame of our service offer we remain focused on your application goals, suggesting the most suitable laser source with the appropriate implementation strategy, and review the possible solutions for you in our laser application laboratory.

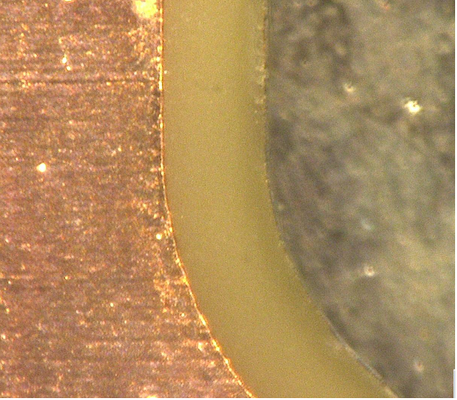

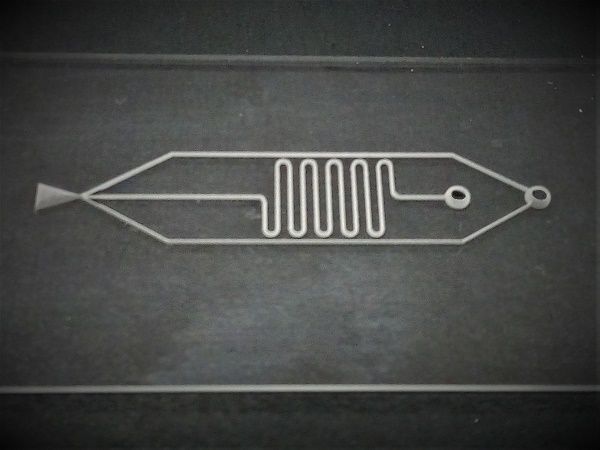

UV Laser Machining of flexible Circuit Boards

The microscope pictures depict quality analysis examples of laser cutting and processing for different industrial machining tasks on printed circuit boards, utilitzing the UV CONQUEROR ALL-IN-ONE as laser source.

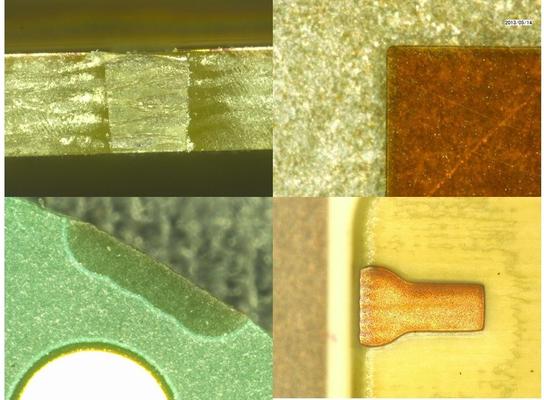

UV Laser Processing of transparent Materials

The UV laser sources of Compact Laser Solutions enable precise machininig of transparent materials via induced micro material removal. The depicted examples were realized on 1mm soda-lime glass(standard microscope object holder glass slides).

UV laser machining of glass